Temporary Replacement Part 3: The Ultimate Guide To Solving Your Temporary Needs

When it comes to temporary replacement part 3, you’re probably scratching your head thinking, “What exactly does this mean?” Well, buckle up, because we’re diving deep into the world of temporary solutions that can save your day—or your entire project. Whether you’re dealing with machinery, electronics, or even staffing needs, understanding temporary replacement part 3 is crucial. It’s like having a superhero in your toolbox ready to swoop in when things go south.

Let’s face it, life happens. Equipment breaks down, components wear out, and sometimes you just need a quick fix to keep things running smoothly. That’s where temporary replacement part 3 comes into play. Think of it as the backup singer who steps in when the lead vocalist gets laryngitis. Sure, it’s not the original, but it gets the job done until the real deal is back in action.

But why does it matter? In today’s fast-paced world, downtime can cost you big time—literally. Whether you’re running a small business or managing a massive production line, having a solid plan for temporary replacements can mean the difference between success and disaster. So, let’s break it down and make sure you’re prepared for whatever comes your way.

What Exactly is Temporary Replacement Part 3?

Alright, let’s get down to brass tacks. Temporary replacement part 3 refers to any component, tool, or even personnel that can temporarily fill a void in your operations. It’s like a rental car when yours is in the shop—it’s not your baby, but it gets you where you need to go. These parts are designed to bridge the gap until the original or permanent solution is ready to roll.

Now, here’s the kicker: not all temporary replacements are created equal. Some are quick fixes, while others are engineered to last for extended periods. The key is knowing what you need and when you need it. For instance, if you’re dealing with a broken conveyor belt in a factory, a temporary replacement might be a smaller, more affordable option that keeps production moving until the big guy is back online.

Why Should You Care About Temporary Solutions?

Here’s the deal: downtime costs money. And not just a little bit—like, serious dough. According to recent studies, manufacturing plants lose billions annually due to unexpected equipment failures. That’s where temporary replacement part 3 comes into play. By having a plan in place, you can minimize the impact of unexpected breakdowns and keep your operations humming along.

But it’s not just about saving cash. Temporary solutions also give you the flexibility to test new ideas without committing to long-term changes. Think of it as trying out a new recipe before you invite the in-laws over for dinner. If it works, great! If not, no harm done.

Top 5 Benefits of Using Temporary Replacement Part 3

Let’s talk turkey here. Why should you even bother with temporary replacements? Here are the top five reasons:

- Cost-Effective: Temporary solutions are often cheaper than buying new parts outright.

- Quick Deployment: You don’t have to wait weeks or months for a permanent fix.

- Flexibility: Test new ideas without making a long-term commitment.

- Minimized Downtime: Keep your operations running smoothly while you fix the real issue.

- Improved Efficiency: Sometimes, the temp solution works better than the original!

When Should You Use Temporary Replacement Part 3?

Not sure when to pull the trigger on a temporary solution? Here’s a quick rundown:

- When your primary component fails unexpectedly.

- When you need to test a new system without full commitment.

- When budget constraints prevent immediate replacement.

- When time is of the essence and you need a quick fix.

Remember, temporary doesn’t mean inferior. In many cases, these parts are engineered to perform just as well as the originals—at least for a while. So, don’t shy away from them when the chips are down.

How to Choose the Right Temporary Replacement Part 3

Picking the right temp solution isn’t as simple as grabbing the first thing you see. You need to consider several factors:

- Compatibility: Make sure the replacement fits seamlessly with your existing system.

- Quality: Don’t skimp on quality just because it’s temporary. Poor quality can lead to bigger problems down the road.

- Cost: Balance cost with performance. You don’t want to break the bank, but you also don’t want something that falls apart after a week.

- Availability: Choose parts that are readily available to minimize delays.

And let’s not forget the importance of consulting with experts. Whether it’s your local mechanic or a team of engineers, getting advice from professionals can save you a headache—or two.

Common Mistakes to Avoid

Let’s talk about what NOT to do when it comes to temporary replacement part 3:

- Ignoring compatibility issues. Just because it looks similar doesn’t mean it’ll work.

- Settling for low-quality parts. Cheap isn’t always better.

- Overlooking long-term consequences. A quick fix today could lead to bigger problems tomorrow.

Remember, the goal is to solve the problem, not create a new one. So, take your time and make an informed decision.

Temporary Replacement Part 3 in Action

Let’s look at some real-world examples of how temporary replacement part 3 has saved the day:

In 2022, a major automotive manufacturer faced a crisis when a critical component in their assembly line failed. Instead of halting production entirely, they implemented a temporary solution that kept the line running at 80% capacity. This allowed them to meet deadlines while they sourced a permanent replacement.

Another example comes from the tech industry, where a startup used a temporary server setup to launch their new app. This allowed them to test the waters without investing in expensive infrastructure upfront. Once they saw the app’s success, they upgraded to a more robust system.

Industry Trends in Temporary Solutions

The world of temporary replacement part 3 is evolving rapidly. Here are some trends to watch:

- Modular Design: More companies are designing equipment with modular components, making it easier to swap out parts quickly.

- 3D Printing: On-demand printing of replacement parts is becoming a game-changer in many industries.

- AI-Powered Predictive Maintenance: Using AI to predict when parts will fail means you can have replacements ready before disaster strikes.

As technology continues to advance, the options for temporary solutions will only improve. Stay ahead of the curve by keeping an eye on these trends.

Cost Analysis: Is Temporary Replacement Part 3 Worth It?

Let’s crunch some numbers. On average, companies that implement temporary solutions see a 20-30% reduction in downtime-related costs. That’s a pretty compelling reason to consider them, right?

But here’s the thing: the cost-effectiveness depends on the situation. For example, if you’re dealing with a high-value machine, the cost of a temporary replacement might be negligible compared to the potential losses from downtime. On the flip side, if you’re working with lower-margin products, the cost might be more significant.

Long-Term vs. Short-Term Benefits

While temporary replacement part 3 offers immediate relief, it’s important to consider the long-term implications. Will the temp solution lead to additional wear and tear on your equipment? Could it impact the quality of your final product? These are questions you need to answer before pulling the trigger.

Where to Find Quality Temporary Replacement Part 3

Not all suppliers are created equal. Here are some tips for finding quality temporary solutions:

- Reputable Suppliers: Stick with suppliers who have a proven track record of delivering reliable parts.

- Online Marketplaces: Platforms like Alibaba and Amazon Business offer a wide range of options, but be sure to read reviews carefully.

- Local Vendors: Sometimes, the best solutions are right in your backyard. Building relationships with local suppliers can pay off big time.

And don’t forget to negotiate. Many suppliers are willing to work with you on pricing, especially if you’re a repeat customer.

Final Thoughts on Temporary Replacement Part 3

So, there you have it—the lowdown on temporary replacement part 3. Whether you’re dealing with machinery, electronics, or staffing needs, having a solid plan for temporary solutions can save you time, money, and a whole lot of stress.

Here’s a quick recap of what we’ve covered:

- Temporary replacement part 3 is crucial for minimizing downtime and maximizing efficiency.

- Choosing the right solution involves considering compatibility, quality, cost, and availability.

- Industry trends like modular design, 3D printing, and AI-powered maintenance are shaping the future of temporary solutions.

Now, it’s your turn. Take what you’ve learned and apply it to your operations. And don’t forget to share this article with your network—knowledge is power, after all. Until next time, stay sharp and keep those operations running smoothly!

Table of Contents

- Temporary Replacement Part 3: The Ultimate Guide to Solving Your Temporary Needs

- What Exactly is Temporary Replacement Part 3?

- Why Should You Care About Temporary Solutions?

- Top 5 Benefits of Using Temporary Replacement Part 3

- When Should You Use Temporary Replacement Part 3?

- How to Choose the Right Temporary Replacement Part 3

- Common Mistakes to Avoid

- Temporary Replacement Part 3 in Action

- Industry Trends in Temporary Solutions

- Cost Analysis: Is Temporary Replacement Part 3 Worth It?

- Where to Find Quality Temporary Replacement Part 3

Is Ari Melber On Vacation This Week? Unveiling The Latest Updates

New South Movie Hindi Dubbed 2025: Your Ultimate Guide To The Hottest Film Release

Unveiling Jean Chow: A Deep Dive Into Her Remarkable Journey And Legacy

Part 3 PDF

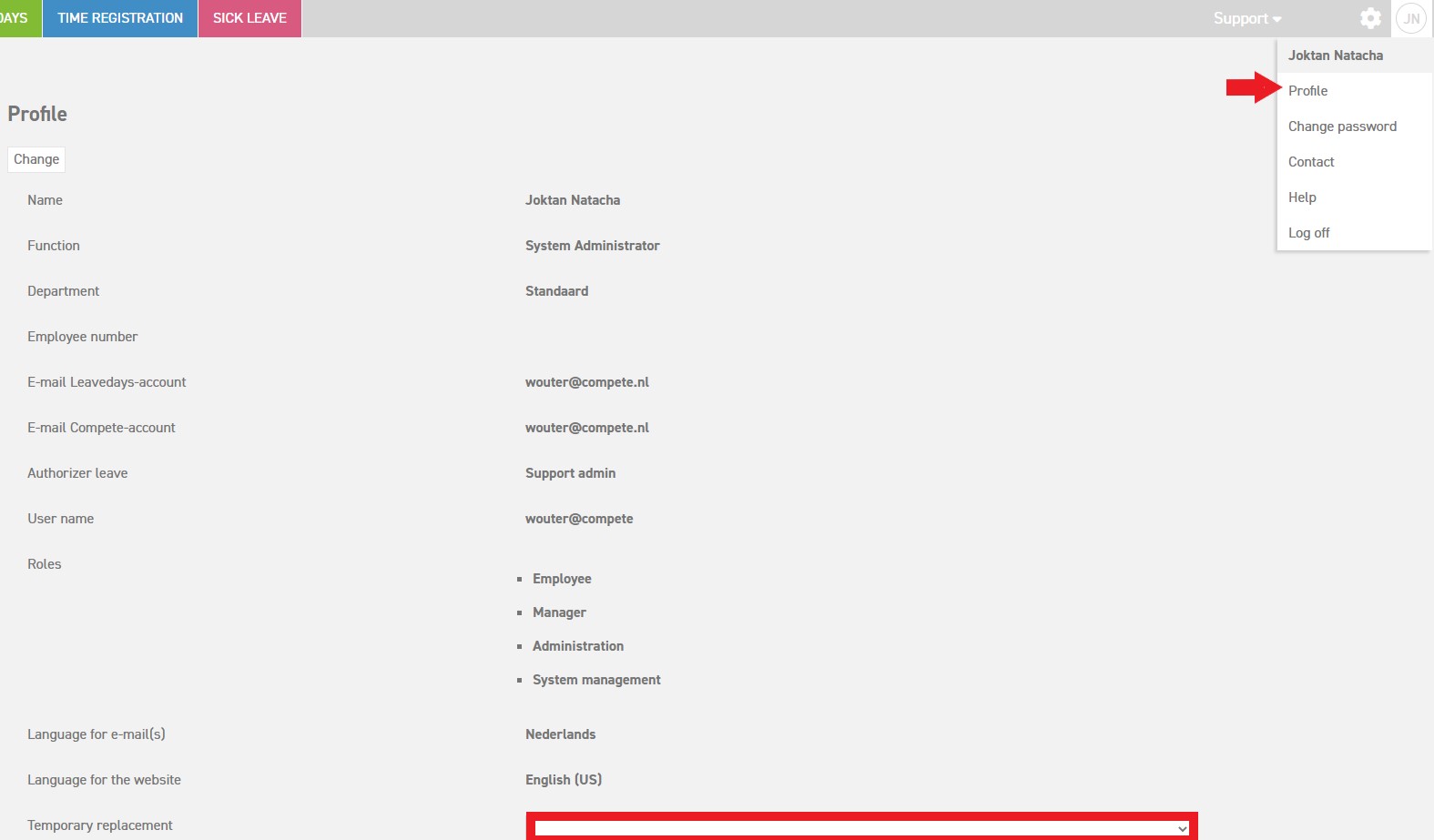

Temporary replacement Leavedays Support

Dentistry REMOVABLE PARTIAL DENTURES…. Temporary...